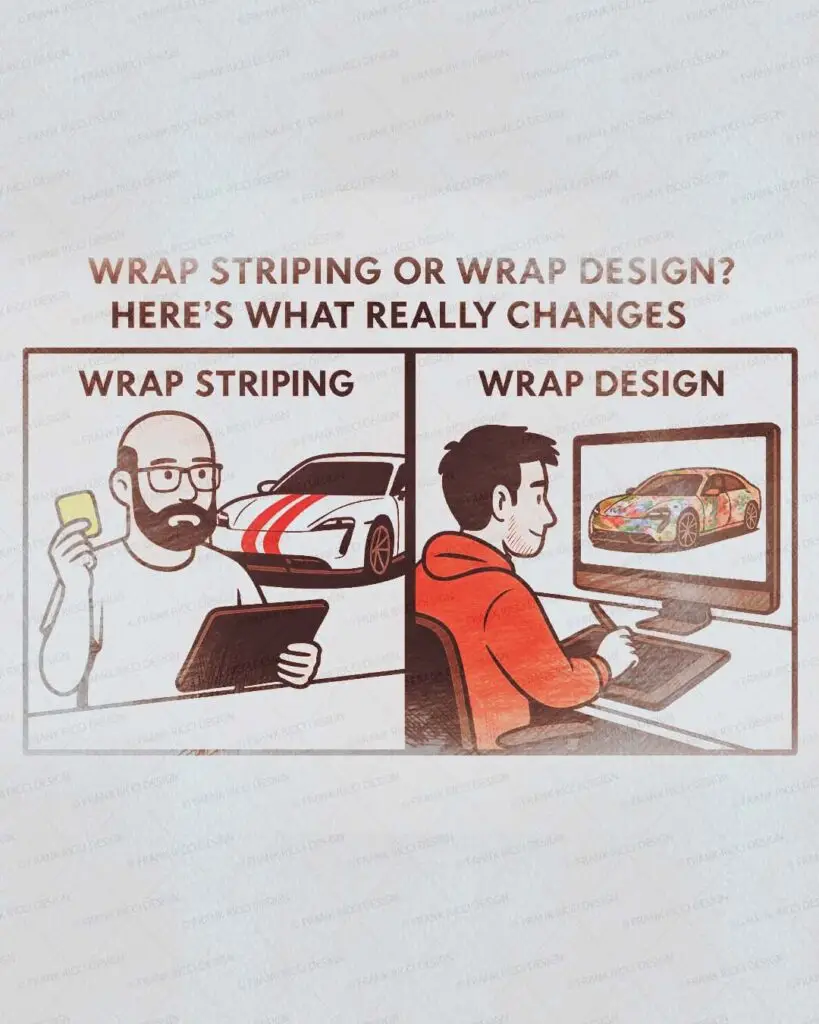

Wrap, Striping or Wrap Design? Here’s What Really Changes

1. Color change and striping: a technical matter

Color change wraps involve fully covering the vehicle with a colored film — matte, glossy, satin, or textured. It can also include extras like dechrome, different finishes on certain zones, or basic racing stripes.

In these cases, the client deals directly with a wrapper, the installer who specializes in applying film. Their technical skills are key: choosing the right materials, prepping the car, applying and trimming with precision.

⏱️ Average timeline: 4 to 10 days, depending on film type and vehicle complexity.

There can be some creative input, but it’s usually limited to color choices, finish combinations, or layout placement. Often, the wrapper suggests quick, effective options without needing a separate designer.

2. Wrap design: building a creative vision

Wrap design is a different game. It introduces the role of a graphic designer, who works on the visual, conceptual, and narrative aspects of the project.

We’re talking about illustrations, custom textures, bespoke graphics, creative patterns — all meant to tell a story. The result is a tailored visual experience.

In this setup:

- The client works with at least two professionals: the designer and the wrapper

- The designer’s work directly affects timing, cost, and final impact

- There’s ongoing dialogue to interpret ideas and turn them into ready-to-print files

⏱️ Average timeline: 1 to 3 weeks, depending on design complexity and coordination

3. How important is the designer?

It depends. If you’re working on a ready-made design (T3) and just need minor edits like color swaps or logo placement, any skilled designer can do the job, as long as they have the original files.

But if the project is custom, complex, or starts from scratch (T1 or T2), the designer matters. A lot. They need to understand how a wrapper thinks, how materials behave, how panels align, and how to tell a visual story through design.

A good designer will listen, decode your ideas, propose directions, and deliver a layout that flows perfectly across every vehicle panel.

4. The wrapper’s role gets harder, too

It’s Not Just Production — It’s Creative Focus

✅ In summary

- Color change is technical, fast, and usually managed by one expert

- Wrap design is creative, layered, and needs collaboration

- As complexity increases, so does the need for a skilled team and smooth communication

The vinyl may be the same — but the process, people, and results are worlds apart.

Ready to bring your wrap project to life?

Want to explore How to Choose the Right Wrap Design for Your Vehicle? Click here ⧉